Environmental Health & Safety from the Director's Desk

|

|

|

|

Welcome to the first EHS newsletter of the year! We are starting 2026 with a major upgrade that will make safety management across our campuses more streamlined, transparent, and efficient. Our transition to the BioRAFT Enterprise system (also known as SciSure) is nearly complete, and this expanded platform brings several new capabilities designed to better support researchers, lab managers, faculty, students and staff.

Several sections of this edition highlight these new features. Look for updates under Hazardous Waste, Industrial Hygiene, and Chemical Safety, where we provide an introduction and primer on how to use the enhanced tools. By mid‑year, we also plan to roll out an improved version of the biomodule. You may hear more about these capabilities during our Laboratory Safety Awareness Week webinars, taking place February 9–13 from 12–1 p.m.

As a special addition, be sure to check the Extra News section for information about the Green Labs program, shared by the UM Sustainability team.

We are excited about what this upgrade means for our research community and look forward to supporting you as we put these enhanced capabilities into action.

Warm regards,

Jennifer Laine, DrPH

Executive Director, EHS

|

|

|

|

Lab Safety Champions of the Year Award Winners

The Lab Safety Champions of the Year Awards (formerly known as the Lab of the Year Awards) were announced during our annual Biosafety Month webinar. We wanted to take a moment to both congratulate these labs and thank them for their commitment to safety. Award winners are labs that observe the standards set by the EHS team, implement best practices, quickly implement corrections to issues when found, and serve as an example for their colleagues to match. One award is granted for each of the 3 University of Miami campuses: Coral Gables, Medical, and Marine. 2025’s award winners are:

Coral Gables Campus: Dr. Kevin McCracken Lab

Medical Campus: Dr. Alejandro Caicedo Lab

Marine Campus: Aplysia Lab overseen by Dr. Claudia Alvarez

Safety Standards for Using Needles and Other Sharps at the U

We ended 2025 with 14 sharps-related incidents at the U, 10 of which involved needles. Nearly all of these incidents occurred in situations that could have been prevented by following established laboratory safety practices. The most common cause of needle sticks continues to be recapping used needles.

As a reminder, recapping needles is prohibited at our university and may only be performed when all of the following conditions are met:

- The research requires recapping.

- An engineering control or approved work-practice control (such as the one handed scoop method) is used to minimize human error.

- The lab’s Biological Hygiene Plan explicitly outlines the engineering or work practice control as a special practice and it has been approved by the EHS Biosafety Team.

Additional best practices to keep in mind include:

- Avoid bending, breaking, or manipulating used needles.

- Never leave sharps unprotected on benches, in drawers, or anywhere they could cause injury.

- Always dispose of both used and unused sharps in designated sharps containers, not in regular trash.

Sharps containers must be removed as biomedical waste once they are ¾ full or when sharps reach the container’s designated fill line.

For more information, please contact us at biosafety@miami.edu.

|

|

|

|

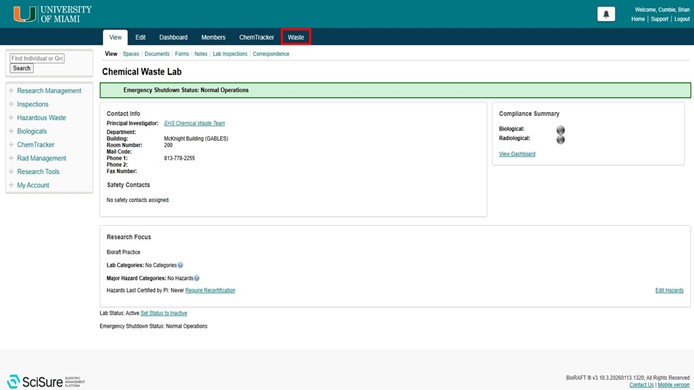

Launch of Chemical Waste Management System in SciSure (BioRAFT)

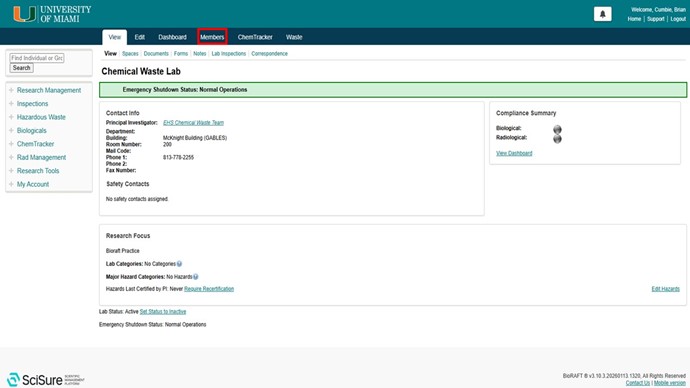

The EHS Hazmat Team is excited to announce that we are now using SciSure (BioRAFT) to manage chemical waste disposal pickups. Over the next several months, EHS will fully transition to processing all waste requests through BioRAFT. The new “Waste” tab should now be visible at the top of your BioRAFT homepage for all PIs and Lab Managers, who may also delegate waste pickup request authority to additional lab members.

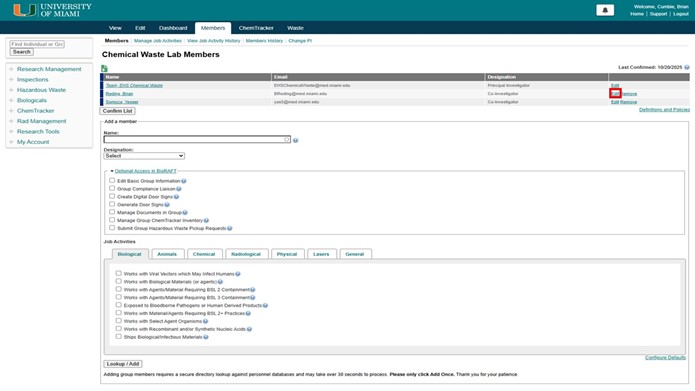

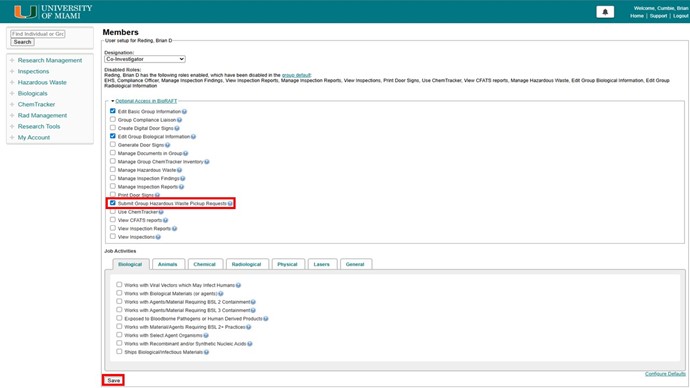

To grant lab members permission to submit waste pickup requests, follow these steps:

- From the lab homepage, select the “Members” tab on the top.

- Select “edit” next to the team member’s name.

- Check “Submit Group Hazardous Waste Pickup Requests”

- Click the “save” button.

|

|

|

|

|

|

|

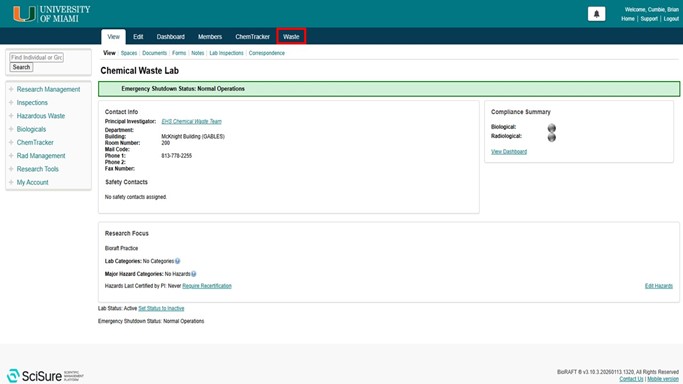

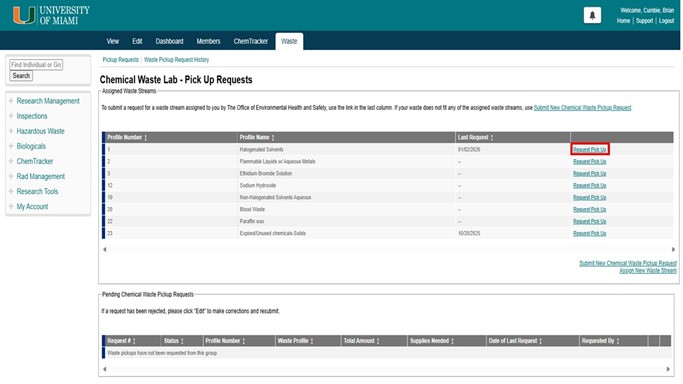

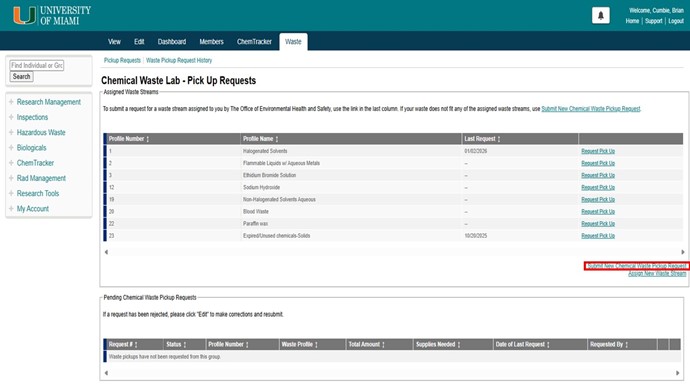

Waste pickup requests are split into two categories: Profiled Wastes and Chemical Wastes.

Profiled Wastes are any wastes that your lab routinely generates. A waste profile can be added to your lab by the EHS Hazmat Team at your request. Please email EHSChemicalWaste@med.miami.edu to have a waste profile assigned to your lab.

Chemical Wastes are all other wastes that your lab generates, such as expired chemicals. The instructions to request waste disposal for each type of waste are found below.

Follow these steps for profiled waste pickups:

- From the homepage, select the “Waste” tab.

- Select “Request Pick Up” in the line next to the waste profile you are requesting to be picked up.

- Fill out the fields in the “Containers” and Location” sections.

- Click “submit”.

|

|

|

|

|

|

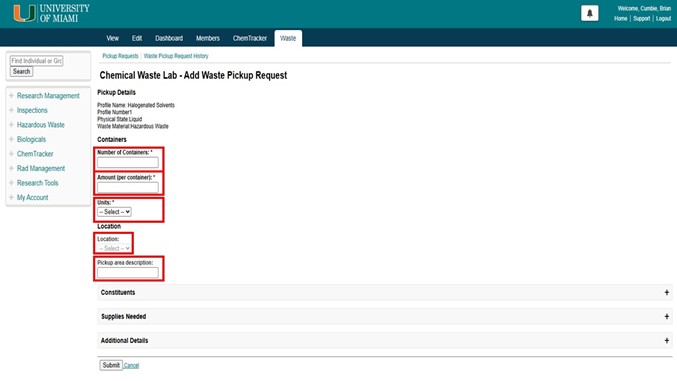

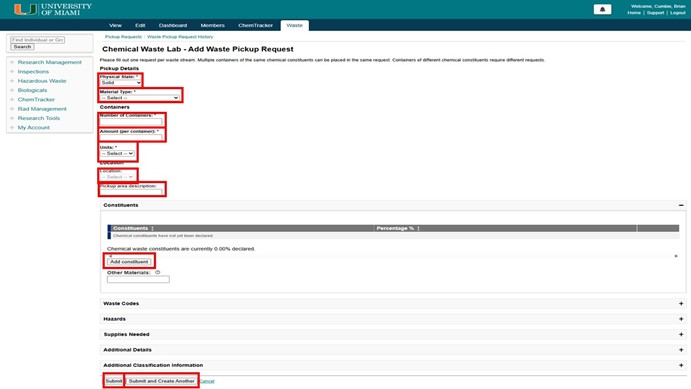

Follow these steps for other chemical waste pickups:

- From the homepage, select the “Waste” tab.

- Select the “Submit New Chemical Waste Pickup Request” button.

- Fill out the fields in the “Containers”, “Location”, and “Constituents” sections.

a. Select “Hazardous Waste” from the “Material Type” dropdown box, unless another selection better fits the waste type.

b. Constituents can be searched by chemical name or CAS Number

- Select “Submit” to finish or “Submit and Create another” if you have additional chemicals to submit.

|

|

|

|

|

|

|

New Respiratory Protection Program Training available in BioRAFT.

The Industrial Hygiene team is excited to announce the launch of our new Respiratory Protection Program training which is available through our laboratory safety platform: BioRAFT/Scishield. This training is designed to help employees and/or students understand:

- When respiratory protection is required

- The different types of respiratory hazards found in the workplace

- How respirators are selected and their proper use

Respiratory protection is required when engineering and administrative controls are insufficient to reduce potential airborne exposure. This training provides foundational knowledge to ensure that academy and research staff and students are properly protected and compliant with federal and local standards.

After completing the training, individuals who are required to wear a respirator to perform work tasks can schedule an onsite fit test with EHS. Fit testing is mandatory before using any tight fitting respirator and must be repeated annually or whenever changes occur that could affect the fit.

Why the Right Respirator Matters

Not all airborne hazards are the same—and neither are all respirators. Selecting the correct respirator depends on the type of contaminant, the exposure level, and the work being performed.

Particulate hazards include dust, fumes, mists, smoke, and aerosols. Examples include:

- Construction related dust

- Wood cutting or grinding activities

- Biological aerosols from tissue sampling or infectious agents (e.g., tuberculosis, SARS CoV 2)

These hazards are typically addressed with air purifying respirators, such as N95s.

Chemical hazards involve vapors and gases that may be toxic or irritating when inhaled, such as:

- Solvents

- Pesticides

- Formaldehyde

These require cartridge based air purifying respirators selected specifically for the chemical hazard.

Regardless of the hazard, respirators must meet the following criteria:

- NIOSH approved

- Appropriate for the specific hazard

- Properly fitted to the user

A respirator that does not fit correctly cannot provide adequate protection. This is why fit testing is required and why surgical masks or non approved face coverings are not acceptable under OSHA regulations.

Finally, keep in mind that facial hair can interfere with the respirator’s seal and prevent proper protection.

To stay protected:

- Determine whether your job tasks require respiratory protection

- Complete the Respirator Protection Program training

- Schedule a fit test with EHS if respirator use is required (complete this form)

|

|

|

|

|

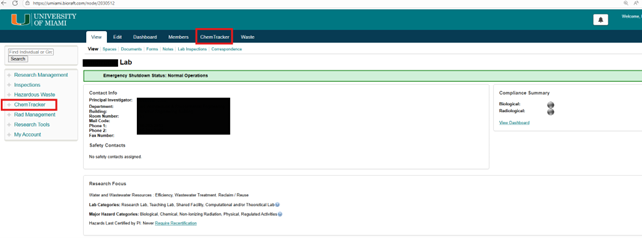

ChemTracker Launch: Strengthening Chemical Management Across the University

Another benefit of the BioRAFT enterprise is the ChemTracker module. This transition reflects the University’s commitment to modernizing chemical management practices and improving the accuracy, accessibility, and reliability of inventory data. With the successful upload of over 54,000 chemical items over 360 laboratories, the University has established a robust foundation for a unified, efficient, and transparent institutional chemical inventory.

ChemTracker is designed to simplify chemical inventory management by connecting users to a centralized database containing chemical and hazard information, regulatory classifications, and container level details. The platform is accessible through any major web browser and allows laboratories to locate chemicals, review hazard data, update inventory information, and access safety documentation in a streamlined and user-friendly environment.

|

|

|

|

|

Improved Access to Inventory Data

Prior to ChemTracker, chemical inventories were maintained using varied excel books, a decentralized method that limited consistency and visibility. The new platform provides researchers and safety staff with real time access to chemical information, including names, synonyms, storage locations, and hazard categories. Users can filter inventory by room or hazard class and search by chemical name or synonym, facilitating efficient day to day laboratory operations.

Faster, More Accurate Reporting

ChemTracker’s integration with a comprehensive chemical database significantly enhances the University’s ability to generate accurate regulatory and safety reports. Hazard classes, regulatory tags, and container attributes are standardized across all laboratories, improving the quality and speed of compliance reporting. This upgrade supports emergency preparedness, regulatory inspections, chemical waste management, and broader safety initiatives.

Greater Completeness and Quality of Inventory Records

The initial upload of 54,000 chemicals ensures the platform begins with a strong baseline of data. Each entry includes essential fields such as chemical name, amount, units, and storage location, strengthening the consistency of inventory information across the institution. This high level of data completeness is critical for hazard assessments, storage compliance, and efficient laboratory management.

A Shared Responsibility: Maintaining Accurate Inventories

Although the data migration was a significant achievement, the long term value of ChemTracker depends on ongoing participation from the research community. Inventory accuracy is a shared responsibility requiring active engagement from laboratories throughout the year.

Key Responsibilities for Laboratories:

To ensure the system remains reliable and up to date, research groups should:

- Add new inventory promptly using the “Add Inventory” feature. ChemTracker allows users to enter chemical information, select matched substances from its database, and provide all relevant container details.

- Edit inventory when materials are moved, consumed, or disposed. The platform supports individual and bulk editing of container details.

- Maintain current SDS documents by using the system’s SDS search function or uploading a local SDS when needed.

- Participate in annual verification to ensure inventory records match physical storage.

By keeping inventories current, laboratories contribute to stronger safety planning, more reliable emergency information, and improved institutional compliance.

Supporting Safety

With integrated hazard information and accessible SDS documentation, the platform enhances researchers’ ability to make informed decisions regarding chemical use and storage. This contributes directly to safer laboratories and more efficient operations.

Moving Forward Together

With ChemTracker live, the University begins a new chapter in chemical inventory management. EHS will continue to provide training and support to help laboratories integrate ChemTracker into their daily workflows. By working collectively and maintaining accurate inventories, we strengthen research safety, improve compliance efficiency, and advance the University’s commitment to excellence in chemical safety.

If you have any questions or would like a consultation, please contact Adrian Hernandez Ferrer.

|

|

|

|

Avoid Leaving Unwanted Items in the Corridor

Removing unwanted items from building corridors is essential for safety, accessibility, and aesthetics. Cluttered corridors can impede emergency evacuations, hinder maintenance tasks, and create an unwelcoming environment.

The Surplus Property Department manages requests for disposal of university owned items across all campuses and satellite locations.

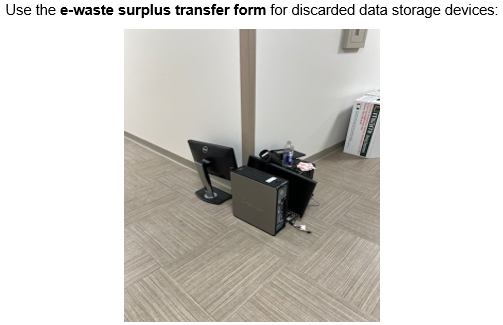

To request the disposal of surplus items like furniture, cabinets, microscopes, or other laboratory equipment, complete the surplus transfer form. For data storage devices (computers, laptops, PCs), use the e-waste surplus transfer form. Once completed, email the forms to surplusproperty@miami.edu to schedule a pickup.

Use the surplus transfer form for discarded office furniture and laboratory equipment:

|

|

|

|

|

|

Let’s all work together to keep the corridors free and clear of all obstructions. A well-organized corridor contributes to a safer and more pleasant building environment, enhancing the overall experience.

For more information, please contact Christine Daley.

|

|

|

|

Transforming Research, Sustaining Tomorrow: Green Lab Certification

|

|

|

|

University of Miami’s Green Lab Program is designed to promote and support world-class science by engaging researchers in best practices to enhance safety, conserve resources, and reduce waste.

This certification helps labs evaluate and address their impact in five key areas: Chemicals and Reagents; Materials and Reuse; Cold Storage; Electronics and Appliances. To be eligible for certification, a lab must prequalify by having no deficiencies on their annual lab safety inspection and/or resolving any minor deficiencies found within 1 month.

To earn a certification, a lab must earn the necessary number of credits across five focus areas in the Green Lab Checklist. Certifications will be awarded on the scale of Bronze to Platinum. Learn more

|

|

|

|