Environmental Health & Safety from the Director's Desk

|

|

|

|

Greetings,

Welcome to the fall edition of your Environmental Health and Safety (EHS) newsletter! As we gear up for the University’s centennial homecoming celebration, we hope you’ll take part in the exciting activities planned throughout the week.

In this issue, you’ll find an announcement outlining our new safety goals. Embedded in every research grant is the expectation that we uphold rigorous safety and compliance standards. Over the past few years, we have made significant strides toward that commitment—and now it’s time to elevate our efforts even further. Together, we can maintain a consistently safe and compliant environment that supports your innovative research.

As always, EHS is here to support you every step of the way.

Warm regards,

Jennifer Laine, DrPH

Executive Director, EHS

|

|

|

|

Fall Focus: Zero Deficiencies in Lab Inspections

As we wrap up the 2025 inspection cycle, it's time to finish strong. Labs are encouraged to resolve all outstanding deficiencies—past and present. University leadership has set the bar high: 100% completion is not just the goal, it's the expectation. This means any deficiencies found this year or at any point in the past, as indicated by SciShield (BioRAFT), must be corrected.

We’ll be reaching out this fall—visiting, calling, and emailing—until every lab hits the mark. A quick check on your lab’s inspection status can go a long way. Your help now makes a big impact—let’s finish the year strong together!

How to Check Your Lab’s Deficiencies in SciShield (BioRAFT)

To see what items may be remaining for your lab, log into SciShield (BioRAFT). From your lab profile, look along the 2nd row of horizontal links at the top of your lab’s dashboard for “Lab Inspections”. On this page you’ll see all previously logged inspections, including this year’s. The 4th column is titled “Resolved Findings”. Completing all findings means that the numerator should match the denominator, i.e. 4 deficiencies noted during the last inspection should read “4 / 4”. To see the deficiencies look at the final column to the right that says “View” to review the findings from that year’s inspection. You can scroll down on this page to “Findings” to get details on what findings were found along with how to implement the corrective action and the regulatory citation for the deficiency. Each deficiency will also indicate whether it’s been corrected or not with a green checkmark for items previously completed.

Correcting Deficiencies in SciShield (BioRAFT)

If you have completed a deficiency, it’s critical that you follow this up under “Correspondence” by clicking on “Resolved Findings” and checking the box for the item corrected detailing what work was completed, even better if you have a picture proving the item was corrected - upload it with the finding under “Attach Documents”. Click on “Submit” to then log the correction. Should you encounter any problems navigating or implementing the corrective actions, you can always call EHS for assistance, we’re in your corner if you need help!

Occupational Health Program (OHP) Enrollment Required for Lab Researchers

One of the most frequently overlooked—but essential—requirements for participating in lab research at the University is enrollment in the Occupational Health Program (OHP). It’s a requirement for every person working with animals or hazardous materials, yet we still meet researchers who have never heard of it.

Essentially, the OHP is tasked with protecting the health and well-being of individuals working with animals or hazardous materials. That means every lab and every worker, whether principal investigator (PI), post doc, scientist, technician, student, and even volunteers all have to complete the OHP Questionnaire.

The program supports these individuals by offering vaccinations, titer checks, screening tests, and training depending on the specific tasks that person is doing in the lab. The OHP is administered by the Employee Health Office (EHO), and it is the responsibility of the PI to ensure all participants in the lab complete the OHP questionnaire. For more information see the EHO website: https://employeehealth.miami.edu/ohp/index.html

Should you have any questions or comments, as always please contact us at biosafety@miami.edu.

|

|

|

|

Biomedical Waste Disposal

In recognition of Biosafety month, our team would like to continue the conversation around biomedical waste management practices in our laboratories. Once a lab has generated biomedical waste, it is important to handle and prepare it safely for proper disposal. Many people are involved in the disposal of biomedical waste after it is generated and leaves your lab, so proper management is crucial. Following the steps below will help lead to a safe and compliant workspace.

- Accumulate and dispose of biomedical waste in impermeable red bags that meet ASTM 1709 and ASTM 1922 standards for puncture and tear resistance respectively. The ASTM standards should be stamped on the bag. If you bought compliant bags and they are not properly stamped, please reach out to EHS Hazmat for more guidance.

- Biomedical waste containers must bear the international infectious substance label and be labeled with the building and room number, street address, and city.

o Helpful hint: EHS suggests pre-printed Avery labels with lab information that can be placed on the bag ahead of starting use.

- There must be enough room left in a biomedical waste bag to be sealed with a strong gooseneck or overhand knot. The general rule is ¾ full is full.

- Sharps must be placed into a sharps container. Leave room to close your sharps containers. Most sharps containers have a "full" line in them.

- Biomedical waste must not be stored on the floor. Biomedical waste bags should be disposed of immediately after it is full. Use a secondary container labeled with the international infectious substance label if bags must be stored in the lab.

- On the Medical campus, take your full waste containers to the designated biomedical waste accumulation area located on your floor.

o Only biomedical waste may be placed in these containers. Gloves and other solid waste is not permitted.

- On the Coral Gables and RSMAES campuses, please submit a signed Chemical Waste Disposal Form to EHS, and EHS will collect and dispose of the containers.

Improper Disposal: Solid Waste in Biomedical Bins

|

|

|

|

|

For your convenience, a table providing vendor and product information for compliant biomedical waste containers and bags can be found on the EHS website under the Environmental Protection & Hazardous Materials tab.

If you have any questions or would like to schedule biomedical waste training for your lab, please contact Brian Cumbie.

|

|

|

|

Holiday Decorating "Do's and Don'ts"

As the holidays approach, EHS wants to remind the University community of some decorating "do's and don'ts:"

|

|

|

|

|

Do's

- Do use UL-listed decorative lights, decorations, and ornaments.

- Do use artificial holiday trees that are fire-resistant and place indoor trees away from traffic.

- Do unplug holiday lights when you leave the office for the day.

- Do remove all decorations, displays, lights, and/or ornaments after the holiday event or prior to the University's annual holiday closure.

Don'ts

- Do not block doorways or fire safety equipment!

- Do not use decorative sprays or hang decorative materials (lights, ornaments, etc.) on any fire protection equipment (fire extinguishers, sprinkler heads, smoke detectors, fire alarm pull boxes, etc.), on or near exits or emergency lights.

- Do not place decorative materials in any manner that could present a fall or trip hazard, or impede egress.

- Do not bring or burn candles, incense sticks, and/or other related devices/accessories.

For more information, contact Christine Daley at 305-243-8443 or c.daley@miami.edu.

|

|

|

|

Understanding Confined Spaces and Engulfment Hazards: What You Need to Know

|

|

|

|

|

In early September, headlines captured a dramatic rescue in Newport Beach, California, where lifeguards saved two children trapped in a collapsing sand hole as the tide surged in. Just weeks earlier, on July 28th, the U.S. Department of Labor issued an urgent trade release emphasizing the importance of safe trenching and excavation practices, following reports of 11 trench-related fatalities in 2025 (U.S. Department of Labor, n.d.). These incidents echo other heartbreaking cases, including the death of a 17-year-old in May 2023 at Cape Hatteras National Seashore, North Carolina, after being buried in a sand hole, and a tragic February 2024 event in South Florida, where a 7-year-old girl lost her life in a similar collapse.

While you might not encounter engulfing hazards in your day-to-day job duties, it might be important to review your awareness level about confined spaces dangers. According to the Occupational Safety and Health Administration (Occupational Safety and Health Administration, n.d.) a Confined Space means a space that: (1) Is large enough and so configured that an employee can bodily enter and perform assigned work; (2) Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits); and (3) Is not designed for continuous employee occupancy.

Confined spaces themselves aren’t necessarily a hazard, but there are conditions that may render confined spaces hazardous, for example, engulfment, which results when a worker is surrounded and overcome by a granular substance such as soil, sand, gravel, sawdust, seed, grain or flour or if submerged in a liquid such as water or a chemical.

In occupational settings the highest risk for engulfment lies in trenching and excavation work. Trench collapses cause dozens of fatalities and hundreds of injuries each year. Excavation is any man-made cavity, hole, or depression in the ground that is created by removing earth (beach sand holes). Trenching is a specific type of excavation that is deeper than it is wide, typically less than 15 feet wide. Trenches are often dug for installing utility lines such as water, sewer, or gas. A single cubic yard of soil can weigh more than 3,000 pounds, which means that even a small cave-in can be fatal. It is important to understand the hazards of these activities and how to control them.

|

|

|

|

|

In workplace settings, never enter a trench unless you are trained to recognize the hazards and it has been inspected by a competent person. Trench collapses, or cave-ins, can be prevented by taking the following steps:

- SLOPE or bench trench walls at an angle inclined away from the excavation.

- SHORE trench walls by installing aluminum hydraulic or other types of supports to prevent soil movement.

- SHIELD trench walls with trench boxes or other types of supports to prevent soil cave-ins.

At home, you can also prevent engulfment hazards by talking about it with your loved ones and sharing the National Park Service’s “Fill Beach Holes” initiative tips:

- Avoid digging deep holes in the sand.

- If you do dig a hole, fill it in before you leave the beach.

- Don’t dig holes deeper than your knees when standing in them.

- If you see an abandoned sand hole, consider filling it in if you can do it safely.

For Confined Spaces awareness training, or if you want to learn more about occupational related topics, please reach out to our Industrial Hygiene team at 305-243-8443 or nxe155@miami.edu.

|

|

|

|

Labeling Matters: A Critical Safety Step in Labs

Laboratory and chemical safety isn’t just a checklist—it’s a shared culture. At the U, our laboratories reflect academic excellence, innovation, and professionalism. But none of that thrives without a strong foundation of safety.

Whether you're a professor driving groundbreaking research, a student mastering chemistry, or a staff member keeping operations running smoothly, everyone plays a role in maintaining a safe lab environment.

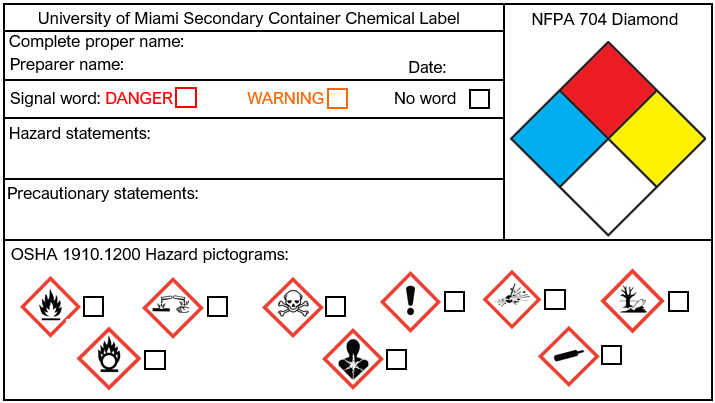

Among the many safety practices, one often overlooked yet critical habit stands out: the practice of properly identifying secondary or non-original containers i.e. labeling temporary workplace solutions for short-term chemical storage or handling.

The Hidden Risks of Unlabeled Secondary Container or Workplace Solutions

Secondary container chemical solutions or temporary chemical/workplace solutions—are commonly prepared for short-term use during experiments or procedures. These solutions may be formulated or transferred into secondary containers such as beakers, flasks, or squirt bottles. While their temporary nature might suggest a lower risk, the opposite is true: failure to label these containers properly can lead to serious accidents!

Imagine a scenario where two clear liquids sit side by side in identical containers. One is a benign buffer solution; the other is a corrosive acid. Without proper labeling, a simple mix-up could result in chemical burns, toxic exposure, or ruined experiments. Misidentifying chemicals remains one of the top causes of lab accidents—a risk that’s entirely preventable with proper labeling and awareness.

To prevent such incidents, every workplace solution must be labeled with:

• The full chemical name (no abbreviations or chemical formula)

• Concentration, if applicable

• Signal word (Danger, Warning or no word for nonhazardous chemicals)

• Hazard information (e.g., corrosive, flammable)

• Hazard pictogram (according to OSHA-GHS)

• Date of preparation

• Responsible person’s name or initials

This practice aligns with OSHA’s Hazard Communication Standard and GHS (Globally Harmonized System) guidelines, ensuring that even temporary containers are treated with the same diligence as permanent ones.

Labeling: More Than Just a Sticker

Effective labeling is not just about compliance—it’s about communication. A well-labeled container speaks volumes: it tells the user what’s inside, how old it is, how to handle it, and what precautions to take. In a shared lab space, where multiple users may interact with the same materials, clear and consistent labeling prevents confusion and promotes accountability.

Handwritten notes on masking tape may fade or peel off, leaving containers unidentified. Investing in proper labels and standardized templates is a small cost for a significant safety return.

If you have any questions or need Secondary Container Chemical Labels, please contact Adrian Hernandez Ferrer.

|

|

|

|

|