Environmental Health & Safety from the Director's Desk

|

|

|

|

Hello everyone,

Welcome to the spring edition of the newsletter! As part of spring tradition, we invite you to kick off spring cleaning in the lab. With the season shifting toward summer, now is the perfect time to refresh your space and create a safer, more efficient work environment.

A clean and well-organized lab fosters not only better productivity but also enhanced safety for research and collaboration. Spring cleaning goes beyond tidying up—it’s about proper storage, removing clutter, and checking equipment to ensure optimal lab performance.

In this issue, we’ll share best practices for organizing work areas, disposing of lab materials properly, and implementing preventive measures to maintain a clean and hazard-free space year-round. Let’s work together to keep our labs safe, functional, and ready for groundbreaking discoveries!

As always, if you need guidance or assistance, don’t hesitate to reach out to the EHS team.

Happy cleaning!

Jennifer Laine, DrPH

Executive Director, EHS

|

|

|

|

New Items for the 2025 Inspection Cycle

The 2025 inspection cycle is underway, and this year’s checklist includes several updates. Each year, we refine the checklist by improving clarity, removing outdated items, and adding new criteria to address emerging safety concerns.

This year’s additions include:

- Respiratory Protection Program Enrollment – Laboratory personnel using respirators must be enrolled in the Respiratory Protection Program. Respirator use is overseen by the EHS Industrial Hygiene team and requires approval before use. If you currently use or anticipate using a respirator, please reach out for guidance.

- Proper Storage and Handling of Cryogenic Materials – Due to multiple cryogenic-related incidents in recent years, we are emphasizing safe practices. Labs must ensure appropriate PPE is available, use male-threaded vials, and regularly inspect frozen vials to prevent potential hazards.

- BioRAFT (SciShield) Profile Updates – Labs must verify that their BioRAFT profile accurately reflects current information, including Research Focus, Spaces, and Members. While all research labs are in BioRAFT, many are underutilizing its capabilities. Moving forward, labs are required to provide details about their research focus, update member lists, and notify EHS if lab locations change to ensure emergency preparedness.

Resources for Inspection Preparation:

For further details, please refer to:

- Lab Inspection Checklist – Guidelines for the 2025 inspection cycle.

- Lab Inspection Cheat Sheet – Additional guidance on checklist items.

For questions or assistance, please contact us at biosafety@miami.edu .

|

|

|

|

Understanding Permissible Exposure Limits

You may have recently seen news about a final rule issued by the Environmental Protection Agency (EPA) under the Toxic Substances Control Act (TSCA) regarding methylene chloride. This rule significantly lowers the exposure threshold limit due to its classification as posing an “unreasonable risk to human health and the environment.” If you're wondering what a Permissible Exposure Limit (PEL) is—or how it relates to workplace safety—let’s break it down.

What Are Permissible Exposure Limits?

When employees encounter chemical or physical hazards in the workplace, this is known as occupational exposure. Various regulatory agencies establish limits to minimize risks and protect workers.

In the U.S., PELs define the maximum level of exposure legally allowed. The Occupational Safety and Health Administration (OSHA) sets PELs at a federal level, although some states enforce stricter limits through State OSHA programs.

PELs are measured in different ways:

- Time-Weighted Average (TWA): Average exposure over a standard 8-hour work shift.

- Short-Term Exposure Limit (STEL): Maximum exposure allowed over a short duration.

- Ceiling Limit (C): Absolute maximum that must never be exceeded.

Chemical exposures are usually measured in parts per million (ppm) or milligrams per cubic meter (mg/m³). OSHA also sets limits on physical hazards, including:

- Noise

- Ionizing radiation

- Vibration

Additional Exposure Limits & Safety Guidelines

- Immediately Dangerous to Life or Health (IDLH): The level at which exposure poses an immediate threat. Example: Carbon monoxide (CO) has an IDLH level of 1,200 ppm—above this, exposure can lead to severe illness or death.

- Threshold Limit Values (TLVs) & Biological Exposure Indices (BEIs): Published by the American Conference of Governmental Industrial Hygienists (ACGIH), these guidelines describe the hazard limit a worker may be exposed to daily without experiencing negative health effects.

- Recommended Exposure Limits (RELs): Issued by NIOSH, defining upper exposure thresholds for hazardous substances.

While OSHA sets federal workplace exposure limits, the EPA also has the authority to establish New Chemical Exposure Limits (NCELs) through its regulatory processes. Both agencies work to safeguard public health and workplace safety under TSCA and the Occupational Safety and Health (OSH) Act.

How We Can Help

Our Industrial Hygiene team provides occupational exposure assessments upon request. Monitoring can be conducted:

- Passively – Badges positioned in the breathing zone.

- Actively – Pumps attached to sampling media, running during a full shift or procedure.

Some of the chemical exposures we routinely monitor include: ✅ Formaldehyde ✅ Isoflurane ✅ Xylene ✅ Dichloromethane (DCM)

If you have concerns about workplace exposure, please contact Noelia Estevez de Rosario.

Resources for Learning More About PELs:

Permissible Exposure Limits – Annotated Tables: https://www.osha.gov/annotated-pels/table-z-1

NIOSH Pocket Guide to Chemical Hazards: https://www.cdc.gov/niosh/npg/pgintrod.html

ACGIH TLV/BEI guidelines: https://www.acgih.org/science/tlv-bei-guidelines/

EPA Assessing and Managing Chemicals under TSCA: https://www.epa.gov/assessing-and-managing-chemicals-under-tsca

|

|

|

Basic Safety Practices for Chemical Safety in Laboratories

Ensuring a safe and efficient working environment is essential in any academic or research setting, especially when working with hazardous chemicals. Adhering to fundamental safety practices helps prevent accidents and creates a productive workspace. One of the simplest yet most important safety measures is maintaining clean, organized benches, tables, fume hoods, and work areas to minimize hazards associated with poor housekeeping.

|

|

|

|

|

Maintaining Clean and Organized Workspaces

A clean and organized workspace is the foundation of laboratory safety. Keeping benches, tables, and fume hoods free of unnecessary items significantly reduces the risk of accidents. Common hazards associated with cluttered workspaces include:

- Falling Bottles and Containers: Overcrowded work areas increase the likelihood of bottles and containers falling and breaking, leading to chemical spills, exposure to hazardous substances, and potential injuries.

- Obstructed Work Surfaces: Limited clear space can hinder the safe handling of samples and chemicals, increasing the risk of spills, contamination, and difficulties in performing precise tasks.

- Increased Risk of Fire: Clutter can obstruct ventilation and heighten fire risks, particularly when flammable chemicals are present. Proper housekeeping ensures flammable materials are stored safely, away from ignition sources.

Chemical Safety Best Practices

- Proper Storage of Chemicals: Chemicals should be stored in designated areas, clearly labeled, and segregated according to their hazard classifications. This prevents accidental mixing of incompatible substances and ensures quick identification in case of an emergency. This also apply to hazardous waste.

- Proper Use of Fume Hoods: Fume hoods play a critical role in minimizing exposure to hazardous fumes and vapors. To ensure their effectiveness, they must remain free from overcrowding by equipment or excessive chemical storage, allowing for optimal airflow and safe operation.

- Use of Personal Protective Equipment (PPE): Appropriate PPE, such as gloves, goggles, and lab coats, should always be worn when handling chemicals. This minimizes the risk of exposure and protects against potential injuries.

- Immediate Cleanup of Spills: Any small chemical spill, no matter how minor, should be cleaned up immediately using appropriate procedures and materials. This prevents the spread of hazardous substances and reduces the risk of accidents.

Consequences of Poor Housekeeping

Neglecting basic safety practices can lead to serious accidents. Common consequences include:

- Accidental Chemical Exposure: Improperly stored bottles and containers can fall and break, leading to unintended exposure to hazardous chemicals, which may cause health issues ranging from mild irritations to severe injuries.

- Contamination of Samples: Clutter increases the risk of cross-contamination between samples, potentially compromising research integrity and leading to erroneous conclusions.

- Increased Risk of Slips, Trips, and Falls: Items left on floors or walkways can cause slips, trips, and falls. Clear, unobstructed pathways are critical for preventing such accidents.

- Fire Hazards: Improper storage of flammable materials and overcrowding workspaces can obstruct ventilation, significantly increasing fire risks. Ensuring safe storage away from ignition sources is vital.

Summary

Implementing basic safety practices is essential for maintaining chemical safety in academic and research settings. Keeping work areas clean, neat, and clutter-free helps prevent accidents and ensures a safe and productive environment. Laboratories can enhance safety by adhering to proper storage guidelines, maintaining fume hoods, wearing PPE, and promptly cleaning spills. Upholding strong housekeeping and chemical safety practices protects individuals and maintains the integrity of research.

For questions or consultations, please contact Adrian Hernandez Ferrer.

|

|

|

|

Avoid Leaving Unwanted Items in the Corridor

Keeping building corridors free of unwanted items is essential for safety, accessibility, and aesthetics. Cluttered corridors can obstruct emergency evacuations, hinder maintenance work, and create an unwelcoming environment.

Proper Disposal of Surplus Items

The Surplus Property Department manages the disposal of university-owned items across all campuses and satellite locations.

To request the removal of surplus items such as furniture, cabinets, microscopes, or other laboratory equipment, complete the surplus transfer form.

For data storage devices (e.g., computers, laptops, PCs), use the e-waste surplus transfer form.

Once completed, email the forms to surplusproperty@miami.edu to schedule a pickup.

Use the surplus transfer form for discarded office furniture and laboratory equipment:

|

|

|

|

Use the e-waste surplus transfer form for discarded data storage devices:

|

|

|

|

Promoting a Safe & Organized Environment

By keeping corridors clear of obstructions, we can maintain a safe, accessible, and welcoming environment for everyone. Let’s work together to ensure that shared spaces remain organized and hazard-free.

For more information, please contact Christine Daley.

|

|

|

|

Glass Waste Management

Broken glass in a laboratory poses significant safety risks, including injuries and contamination. Proper handling and disposal practices are essential to prevent accidents and maintain a clean, efficient workspace.

Understanding the Risks

Broken glass can lead to serious injuries, including punctures, cuts, and lacerations—some of which may result in infections if not treated properly. Additionally, shattered glass can contaminate experiments and samples, potentially compromising research integrity. Preventing these risks is critical for ensuring a safe and effective laboratory environment.

Immediate Response

When glass breaks in a laboratory, prompt action minimizes risks. Follow these steps:

- Ensure Safety – Clear the area to prevent accidental injuries.

- Wear Protective Gear – Use thick gloves and closed-toe shoes before handling broken glass.

- Use Proper Tools – Collect glass shards using a dustpan and broom or a vacuum hose attachment.

- Never clean up broken glass with your hands.

Proper Disposal of Broken Glass

Safe disposal of broken glass prevents further hazards. Adhere to these guidelines:

- Containment – Place the collected glass in a designated broken glass container, sturdy cardboard box, or plastic container with a lid.

- Labeling – Clearly label the container as "Broken Glass" to alert others of its contents.

- Disposal – Ensure the container is securely sealed to prevent injury. Place it next to your normal waste container for proper disposal. *Note: Containers that held a p-listed (acutely toxic) waste must be disposed of through EHS.

Managing Single-Use Glass Products

Glass pipettes, ampoules, and vials are frequently used in labs for convenience and efficiency. For proper disposal:

- Use a broken glass box with a liner for routine glass waste.

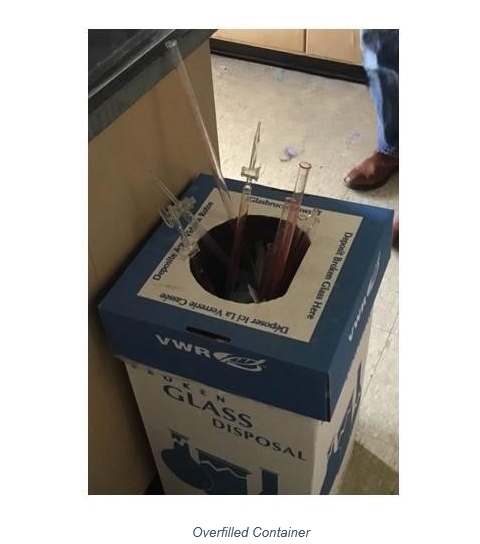

- Do not overfill the container or attempt to compact waste – it increases injury risks.

- Follow manufacturer instructions when closing the container and place it near normal bins for disposal.

|

|

|

|

|

Preventive Measures to Reduce Breakage

The best way to manage glass risks is to prevent breakage altogether. Consider these precautions:

- Use Alternatives: Opt for plastic or tempered glass containers, which are less prone to shattering.

- Secure Glassware: Store items safety, away from edges, to minimize falling risks.

- Textured PPE: Wear gloves with textured fingers to improve grip on glass containers.

- Education: Train lab personnel on best practices for handling glass safely.

Summary

Proper glass waste management is essential for laboratory safety and cleanliness. By following safe handling, disposal, and preventive measures, labs can minimize accidents and protect research integrity. Encourage education and adherence to these guidelines for a safer, more productive work environment.

For questions or assistance, contact Brian Cumbie at bxc933@miami.edu.

|

|

|

|

Need more information or have any questions?

|

|

|

|